Let’s start from how quartz stone is made. Making quartz stone is just like making cookies. First, mix the raw materials such as flour, cream, eggs and other ingredients according to a certain ratio. Second, make the shape and color it. Then put it in the oven and bake it. The raw materials of quartz stone are more than 90% of natural quartz crystal/powder, resin, catalysts, UV inhibitors and pigments, etc. After making the color and texture, put it in the vacuum compressor and heat in the thermo-cure machine.

So first, let’s identify the quality of the raw materials.

1. High-purity quartz crystal/powder

Quartz is a natural mineral that has strong hardness properties. High purity quartz stone crystal/powder which looks more clear can ensure the hardness and scratch resistance, wear resistance and surface polishing glory of quartz stone slab.

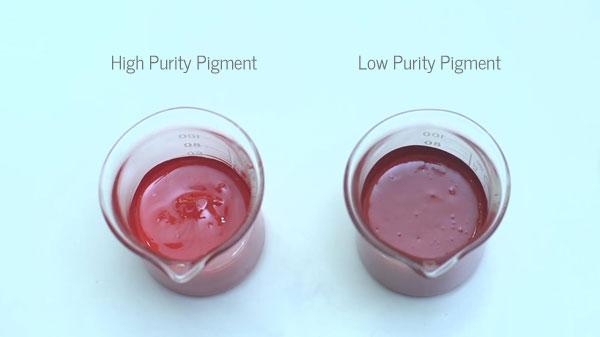

2. High-quality pigments

High-quality pigments have stable hue and strong covering power which makes the colors look more beautiful and natural. Also, they effectively resist UV erosion and prevent oxidation, keep quartz colors from aging and yellowing for a long time.

3. High-performance of polymer resin, catalysts, and UV inhibitors

The polymer resin makes quartz stone completely nonporous. That’s why quartz stone has strong stain-resistant. It also gives quartz stone a little more flexibility to resist from breaking.

High-performance resin which is clean and bright, contains no impurities. It has high unsaturated performance and good adhesion, and is stable and not easy to become yellow.

Common resin which is cloudy, contains high ethane. It is harmful to health.

And then it should be professional in production.

1. Mix raw materials thoroughly and evenly to avoid color spot.

2. Compact the well mixed raw materials with advanced vacuum vibro-compressing machine, remove any space between the ingredients to make a dense non-porous structure.

3. Heat the raw slabs evenly with advanced thermo-cure machine and the setting of well proven parameters, make a better combination of other materials and resin.

4. Well polish the slabs, ensure the surface smooth enough to have long-term stain resistance and clean-ability.

With the above knowledge, we can check some points easily.

1. Color

Check the surface of quartz stone for color spot, impurities and holes by eyes.

2. Purity of quartz

Dip quartz stone in white vinegar and check if little bubbles appear. If yes, it’s not pure. Because that’s calcium carbonate reacts with vinegar and produces bubbles.

3. Hardness, scratch-resistant and wear-resistant

Scratch quartz surface by a sharp key or a knife. If the quality is high, it will appear a grey line, which is the steel powder from the key or knife. You can wipe it off easily. If the quality is low, it will appear a scratching mark on the surface which you can’t remove easily.

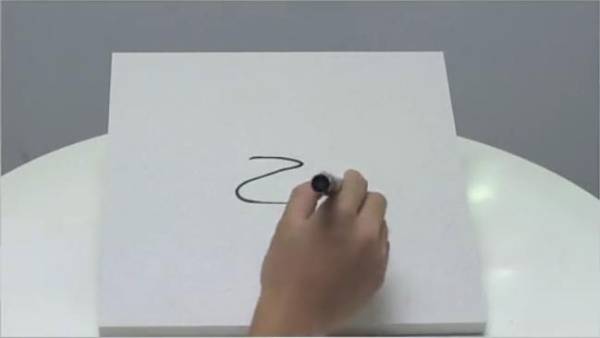

4. Non-porous structure and strong stain resistance

There’re several ways to check. You can write on a quartz surface with a marker pen, clean it with a rag, then check if it can be cleaned or not.

You can also spill red wine, vinegar, coffee on it, then check if it can be cleaned or not.

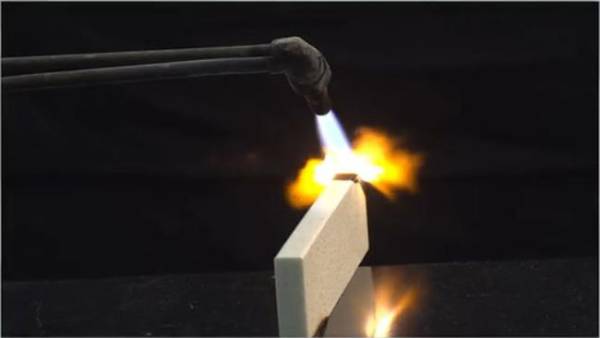

5. Fire-proof, strong heat resistance for high temperature.

Quartz sand has a high melting point of 1300 Celsius itself. With a small % of the ingredients, good quality quartz stone is heat-resistant with temperature under 300℃ and is fire-proof. You can check it by a lighter or a lit cigarette and see if it’s charred?

You can burn on fire to see if it’s fire-proof.

For more specific technical data, it should be done by the professional quality inspection agencies.